Production process

Organic compounds

01.

RECIPE

In the preliminary phase COMET receives the technical specifications and the type of item to be created from the Customer. In the laboratory, the Technical Office evaluates the compatibility with an already existing recipe or defines the specification.

02.

DOSING

The small ingredients of the recipe are weighted by means of a dedicated system which automatically prepares the bags intended for production and at the same time guarantees the traceability of the individual batches.

03.

BANBURY

All the components of the recipe are prepared and mixed in a Banbury where the mixture, processed at temperatures above 100°C, reaches an almost complete level of homogeneity.

04.

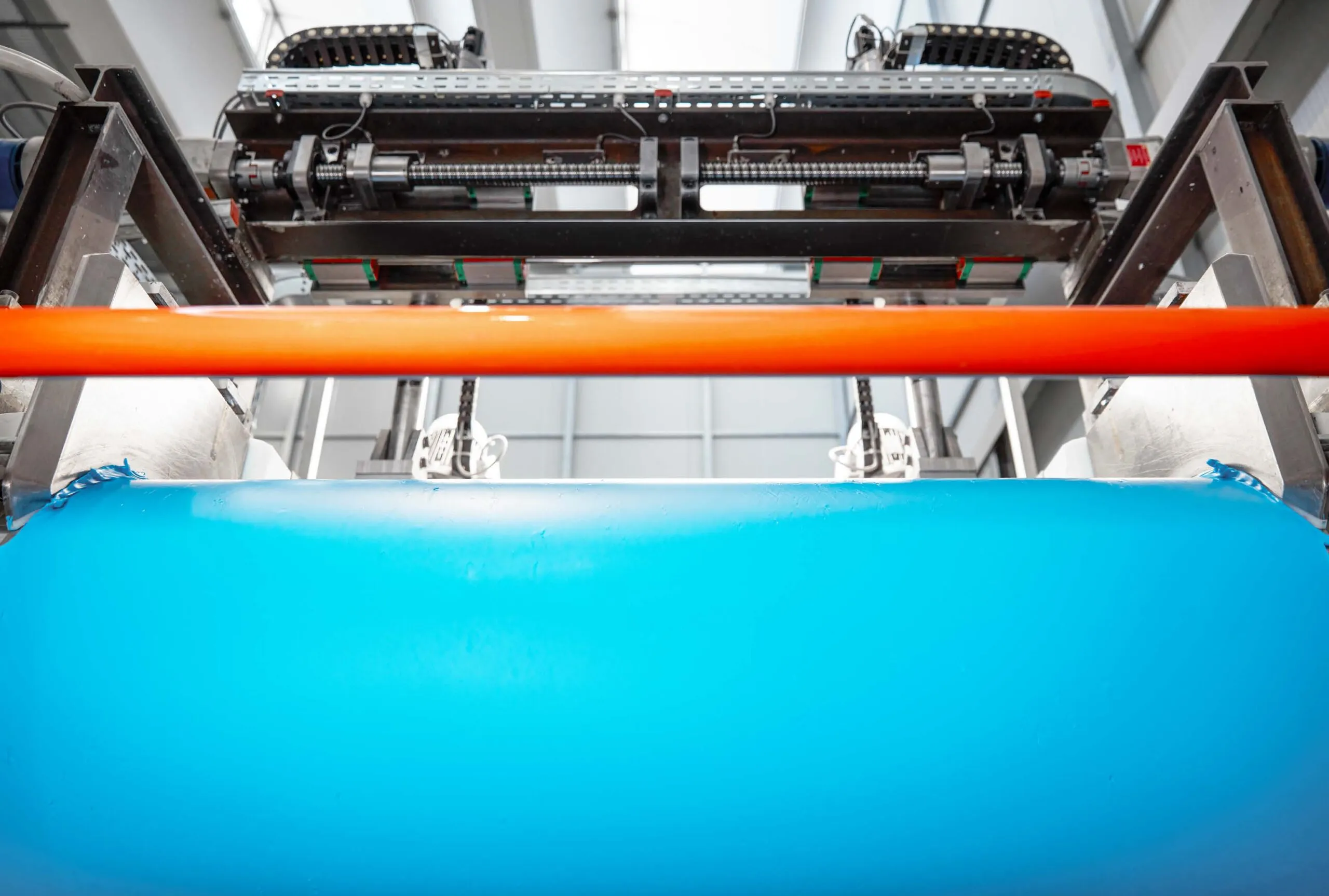

MILL

The mix is conveyed into the CTE and undergoes an initial cooling before being processed on the open mill, reaching perfect homogeneity. Now the mix can be called “compound”.

05.

COOLING

The passage from the open mill allows the operator to withdraw a sample at regular intervals of 3 minutes and to carry out the rheometric control on 100% of the production. At the same time, the compound sheet is cut and enters a water and air cooler, the Batch-Off.

06.

FORM OF PRESENTATION

The rubber compound produced is packaged according to the customer’s choices, in pre-cut strips or endless wide strips. Subsequently it can go through finishing to be rolled up into coils or extruded into a narrow strip, possibly filtered, or preformed into slabs without anti-tack.

07.

CONTROL TEST

All compounds are subjected to various series of control tests (hardness, density, mechanical characteristics) certified by the “certificate of analysis”.

08.

STORAGE

Comet has two automated warehouses in fully air-conditioned environments. The storage is temperature-controlled (between 18° C and 25° C) and involves raw materials, intermediate products and finished products before proceeding with shipment.

09.

SHIPMENT

The pallets packaged for customers are extracted from the automatic warehouse and loaded onto the vehicles of selected forwarders, who will take care of the delivery.

Production process

Inorganic compounds

01.

RECIPE

In the preliminary phase COMET receives the technical specifications and the type of item to be created from the Customer. In the laboratory, the Technical Office evaluates the compatibility with an already existing recipe or defines the specification. The color comparison (RAL reference or simple colorimeter check) is important to choose the mix of pigments to be combined in the recipe together with the silicone base, any master, additives, catalyst and other necessary ingredients.

02.

PREPARATION

All the ingredients starting from the base/s are weighed in the right proportions depending on the size of the order to be produced at the open mill. In the case of twin-screw processing, the dosages are semi-automatic and the weights are always fixed, based on the batch filling/weight.

03.

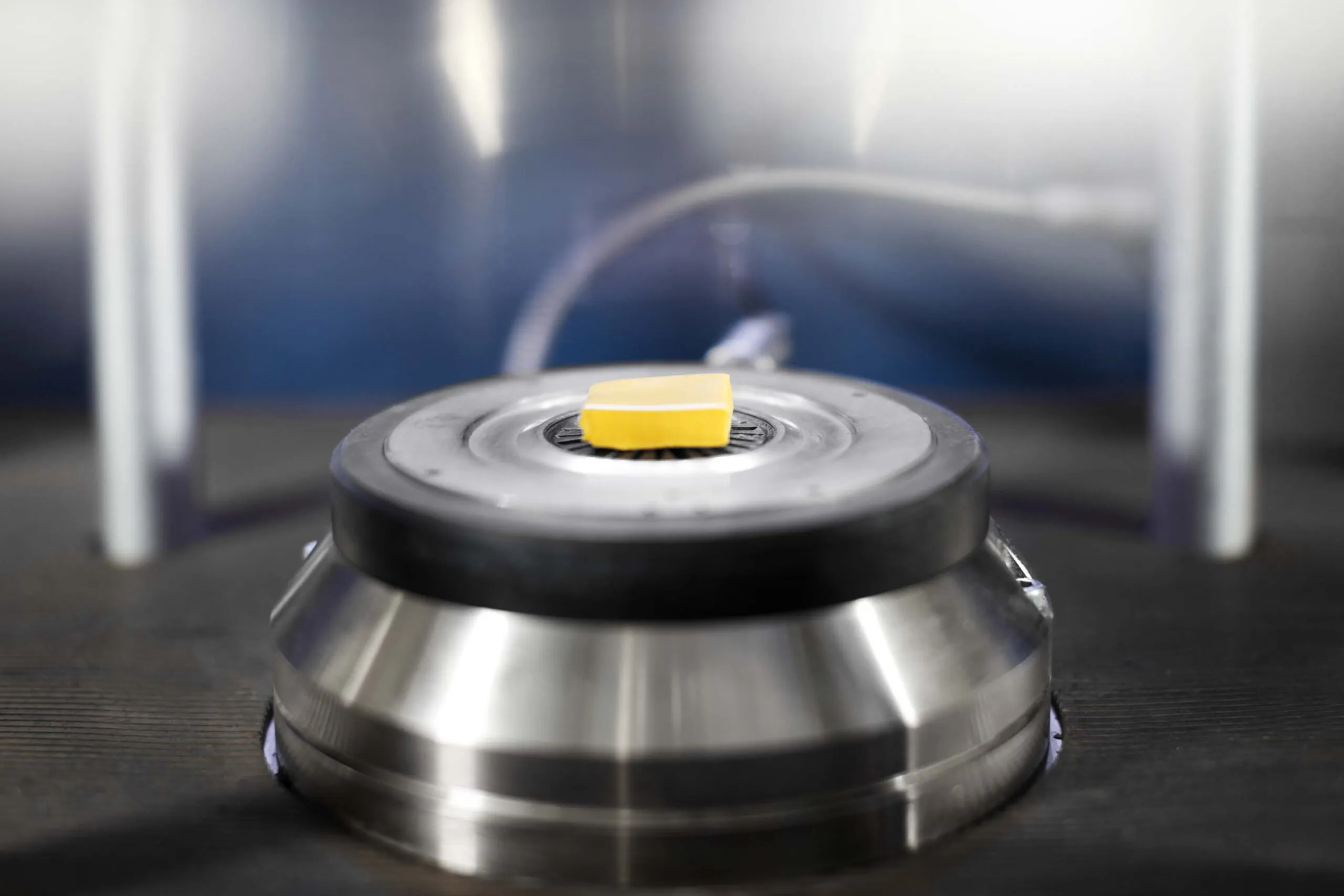

MIXING

All the dosed components are introduced into the twin screw, or incorporated into the base of an open mill. Everything is mixed for a well-defined time, in order to obtain a perfect compound with a uniform color.

04.

FORM OF PRESENTATION

Once the silicone compound is unloaded from the mixer, it is coupled with embossed polythene and packaged in rolled plates, flat sheets or billets, or in a continuous strip, possibly filtered and powdered or wrapped in polythene. It is then left to rest in a small cooling room, before being transferred to the main warehouse.

05.

CONTROL TEST

All compounds are subjected to various series of control tests (hardness, density, mechanical characteristics) certified by the “certificate of analysis”.

06.

STORAGE

Comet has two automated warehouses in fully air-conditioned environments. The storage is temperature-controlled (between 18° C and 25° C) and involves raw materials, intermediate products and finished products before proceeding with shipment.

07.

SHIPMENT

The pallets packaged for customers are extracted from the automatic warehouse and loaded onto the vehicles of selected forwarders, who will take care of the delivery.