The main characteristics of the articles created for use in the infrastructure sector depend specifically and bindingly on the project conditions of the same.

We can find materials with high mechanical performance, resistant to tearing or abrasion and more generally to wear, especially for molded products.

Just as we can have materials with medium mechanical performance but very high resistance to atmospheric agents and UV rays, this is often the case with extruded articles.

Other important aspects may be represented by the resistance to low and high temperatures and the resistance to fire and the high cohesion of the ash (use in safety systems, such as electrical insulation cables).

Manufacturable products

Organic and silicone compounds developed for extrusion, continuously vulcanizable (BSF, UHF, hot air) for the most varied applications (e.g. door seals, gates etc.)

Compounds developed for extrusion for the curtain wall sector, vulcanizable in a bath of molten salts (FC profiles) and compatible with structural silicones

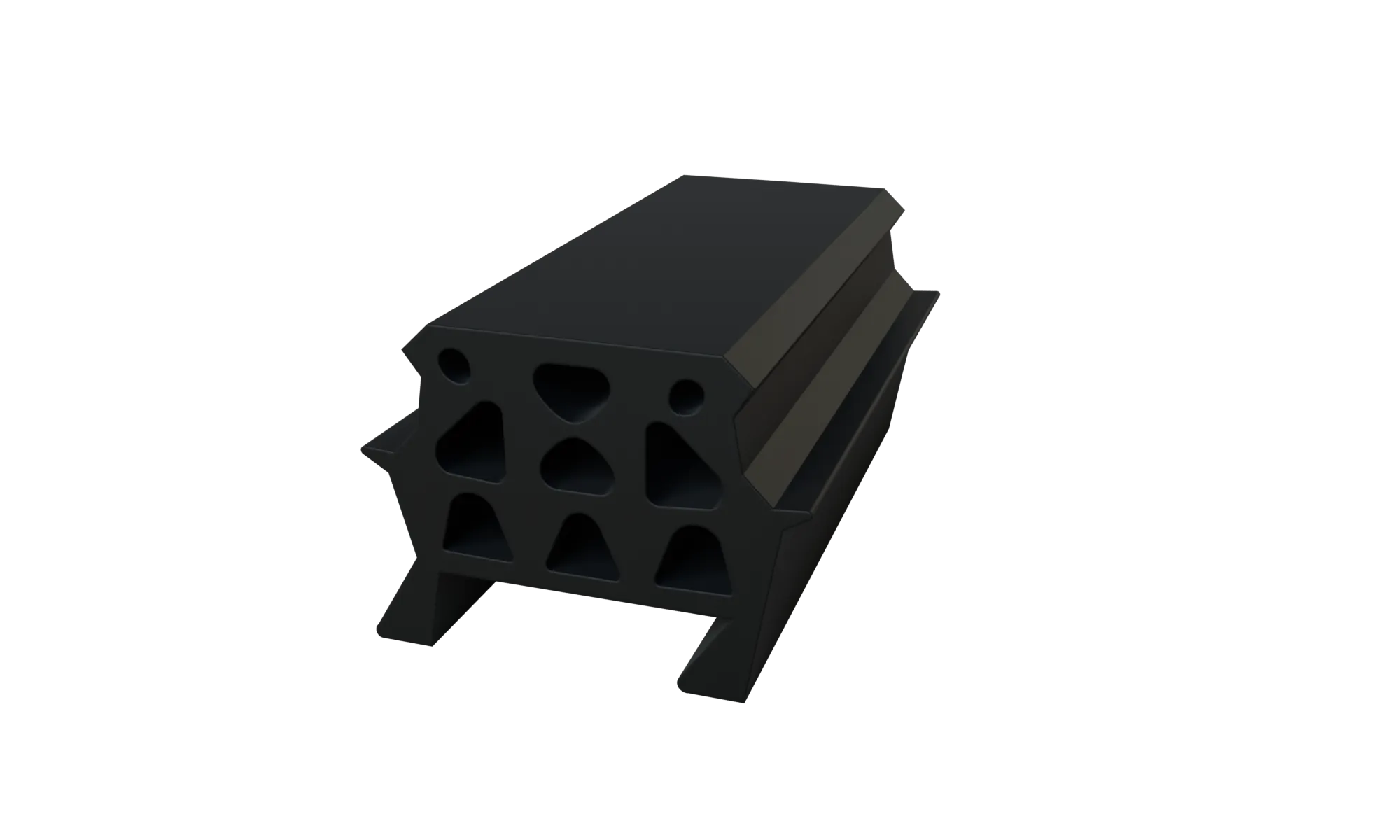

Compounds developed for extrusion for the tunneling sector (gaskets for segments assembled in tunnels), continuously vulcanizable (BSF, UHF, hot air)

Organic rubber compounds developed for extrusion compatible with plexiglass, vulcanizable both in a molten salt bath and in an oven (building profiles)

Compounds for injection or compression molding for anti-vibration and anti-seismic systems

Silicone compounds for temperature resistance -100°C/+300°C

Silicone compounds for pipes and safety cable insulation

Silicone compounds for fire resistance and low smoke opacity

Organic rubber and silicone compounds for technical articles